In the world of reinforced concrete, rebar detailing is the invisible craftsmanship that strengthens every slab, beam, and column. At Built in BIM, our Rebar Detailing Services ensure precision, performance, and project success by translating structural intent into fabrication-ready detailing.

Whether you’re building residential high-rises or industrial infrastructure, our rebar drawings and 3D models make sure every steel bar is bent, placed, and tied exactly as intended—no guesswork, no compromise.

Detailed, dimensioned drawings indicating bar size, shape, spacing, number, and location for all concrete elements.

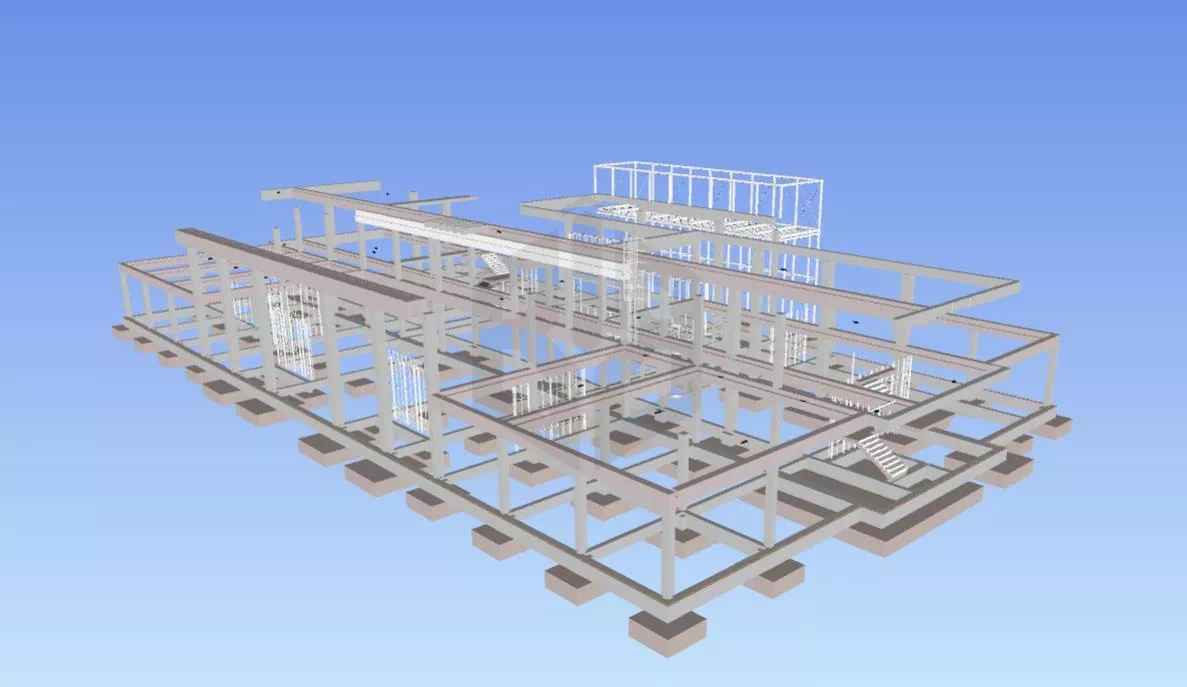

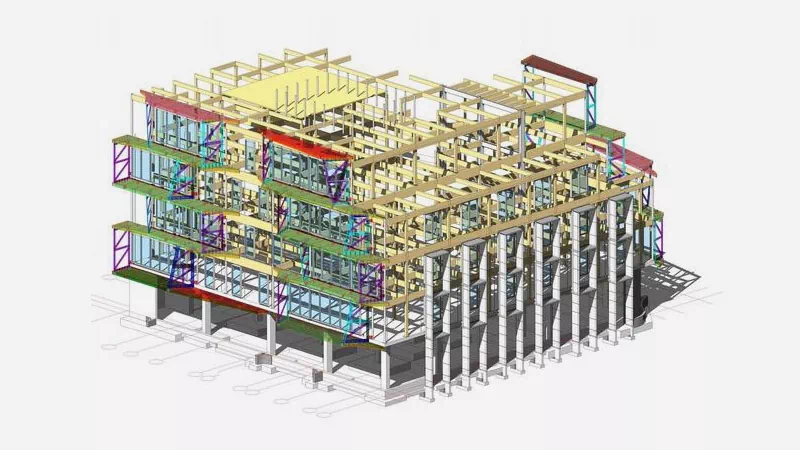

Accurate 3D reinforcement models that enhance visualization, clash detection, and coordination with structural and MEP systems.

Comprehensive tabulation of all rebar, including cut length, shape codes, quantity, and weight for procurement and fabrication.

Fabrication-ready shop drawings showing placement, lap lengths, and splicing aligned with construction sequences.

Precise reinforcement detailing for mat foundations, pile caps, strip footings, and grade beams.

Element-wise rebar layout based on design loads and structural analysis results.

Clash-free detailing coordinated with structural, MEP, and architectural components.

All drawings and documents conform to project-specific, regional, and international codes and standards.

Our rebar detailers work in tandem with structural engineers and BIM modelers to ensure structural integrity, feasibility, and buildability.

We use 3D BIM workflows to eliminate interference between reinforcement, embeds, and service ducts—saving time and costs on-site.

We deliver code-compliant detailing based on ACI, BS, Eurocode, IS, and project-specific guidelines.

Our output is suitable for direct fabrication and field placement—minimizing RFIs and installation errors.

Our accurate BBS and cutting diagrams support prefabricated rebar cages and modular concrete construction.

Multi-level quality checks and agile workflows ensure we meet your construction schedule without compromising on precision.

Our clients span the full construction ecosystem:

Structural drawings, IFC models, design notes, codes, and bar standards are received.

Our engineers review RCC design to determine reinforcement logic and design intent.

We create shop drawings and corresponding BBS with optimal bar spacing, anchorage, and cover.

Each drawing is validated for constructability, tolerance, and code compliance.

Client comments and on-site realities are addressed to refine the output.

We deliver DWGs, PDFs, BBS, and 3D models—all ready for fabrication and construction.

Discover how Built In BIM delivered a smart and adaptive approach to Building Information Modeling. From detailed modeling to seamless data integration, see how we deliver value-driven solutions. Get in touch to learn more!

Yes. We work with both mm and inches as per project region.

Absolutely. Each BBS includes shape codes, bending instructions, and total cut lengths.

We need RCC layout drawings, structural notes, and general specifications.

Yes, we export IFC-compatible models and conduct BIM coordination checks.

When concrete is the foundation, rebar is the backbone. At Built in BIM, our Rebar Detailing Services strengthen your structure from within—cutting costs, saving time, and eliminating rework. Ready to reinforce your next project with precision? Contact Built in BIM today for a free consultation or sample rebar package.

Feel free to reach out to us for any inquiries or to discuss your project needs.

Call us today for personalized coaching and transformative growth!

Email us now for expert coaching and tailored growth solutions!

Visit us for personalized coaching and guidance toward lasting success!

In today’s fast-paced construction environment, plumbing systems are no longer isolated design...

Introduction to MEP BIM for HVAC Systems Mechanical, Electrical, and Plumbing (MEP) Building Inform...

In the US construction industry, BIM has moved far beyond 3D visualization. Today, BIM models direct...