Outsourcing LOD 400 CADmep modeling—especially for MEP fabrication—presents significant opportunities for cost savings, efficiency, and scalability, yet also raises important questions about quality, compliance, and project management when comparing offshore and U.S. vendors. Here’s a detailed, data-driven analysis covering all key aspects.

What LOD 400 CADmep Modeling Involves and Its Importance

LOD 400 describes a high level of detail in BIM modeling, particularly focused on fabrication and installation specifics. At this stage, models contain exact component geometry, assembly details, and information suitable for shop drawings, material takeoffs, and direct field installation. This depth of detail is critical to avoiding costly fabrication errors and ensuring a smooth workflow from digital design to on-site construction.

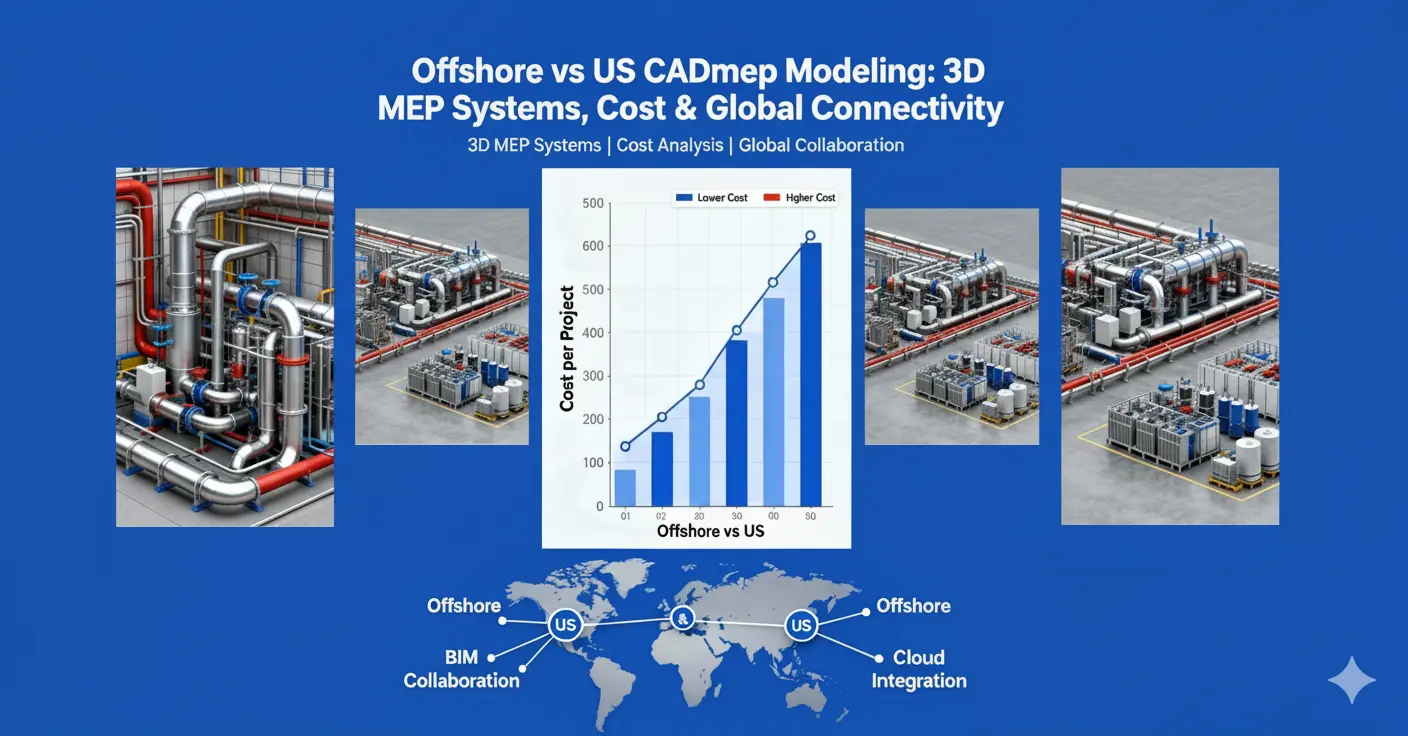

Typical U.S. Vendor Pricing vs Offshore Pricing (India, Eastern Europe)

U.S.-based LOD 400 CADmep modeling services typically cost between $100–$180 per hour, with rates reflecting extensive local expertise and greater regulatory compliance. Offshore vendors in regions like India often charge $20–$50 per hour for equivalent deliverables. Eastern Europe falls in the $35–$70 per hour range, offering a balance of technical proficiency and partial time zone alignment with the U.S. Offshore savings are significant, but careful vetting is needed to ensure deliverable quality and process transparency.

- U.S. Vendors: $100–$180/hour — Premium local services, direct oversight

- India: $20–$50/hour — Large talent pool, best value

- Eastern Europe: $35–$70/hour — Technical skill, closer time overlap

Key Cost-Saving Factors, Time Zone, and Communication Challenges

By outsourcing LOD 400 CADmep modeling, companies tap into cost-efficient labor markets and scalable teams, but must navigate time zone gaps and communication hurdles. While time zone differences allow for 24-hour project cycles, they can delay feedback and reviews if not managed proactively. Language skills, technical documentation standards, and cultural differences also influence project fluidity—making the choice of vendor and collaboration tools crucial to success.

Quality Trade-offs

- Accuracy & Deliverables: U.S. vendors have a strong track record for code compliance, accuracy, and ready-to-install files. Top offshore teams can match this quality but require well-defined project briefs and diligent oversight.

- Standard Compliance: Domestic providers have deep familiarity with codes like SMACNA, ASHRAE, and NFPA. High-caliber offshore partners often work to these standards but may need more guidance or review loops to ensure consistency.

- Turnaround Times: Offshore time zones offer overnight progress, but real-time coordination is best served by domestic vendors when schedules are tight or requirements are fluid.

How Contractors and BIM Managers Decide

Contractors and BIM managers weigh expertise, project scale, budget, and the need for direct oversight. Many use a hybrid approach: sending repetitive or large-batch detailing offshore, while retaining sensitive or client-facing work with U.S. partners. The decision often hinges on experience with the vendor, internal team strengths, risk management, and client preferences.

Best Practices for High-Quality Outsourcing

- Clearly define deliverables, standards, and review milestones upfront.

- Use shared project management/BIM platforms for issue tracking and file handover.

- Start with a sample or pilot project to test communication and deliverable quality.

- Schedule regular progress check-ins and maintain transparent communication.

- Specify file formats, naming, and software requirements to ensure compatibility.

- Perform periodic model audits for accuracy and code compliance.

Built in BIM Expertise & Free Quote

Built in BIM brings years of hands-on expertise delivering advanced LOD 400 CADmep and MEP modeling for projects across the U.S. and globally. The team excels in precise fabrication-ready models, meticulous coordination, and clash detection using leading platforms like Revit and Navisworks— all in strict alignment with U.S. codes (SMACNA, ASHRAE, NFPA, and customized BIM Execution Plans). Built in BIM’s scalable services, deep industry knowledge, and proven track record across complex sectors enable seamless collaboration, cost control, and high-quality results.

Get a competitive edge on your next MEP or fabrication project—contact Built in BIM for a free, no-risk quote and experience the difference that data-driven quality, reliability, and U.S. standards compliance can make to your LOD 400 modeling workflow.

Conclusion

Offshore partners deliver compelling cost efficiencies and rapid scaling for clearly defined, high-volume MEP detailing, provided robust QA processes and transparent project management are upheld. U.S.-based vendors remain the gold standard for technically complex, high-liability projects demanding real-time communication and guaranteed code compliance. For most contractors, a hybrid strategy—offshoring production, while keeping sensitive QA in-house—provides the ideal blend of cost savings and quality.